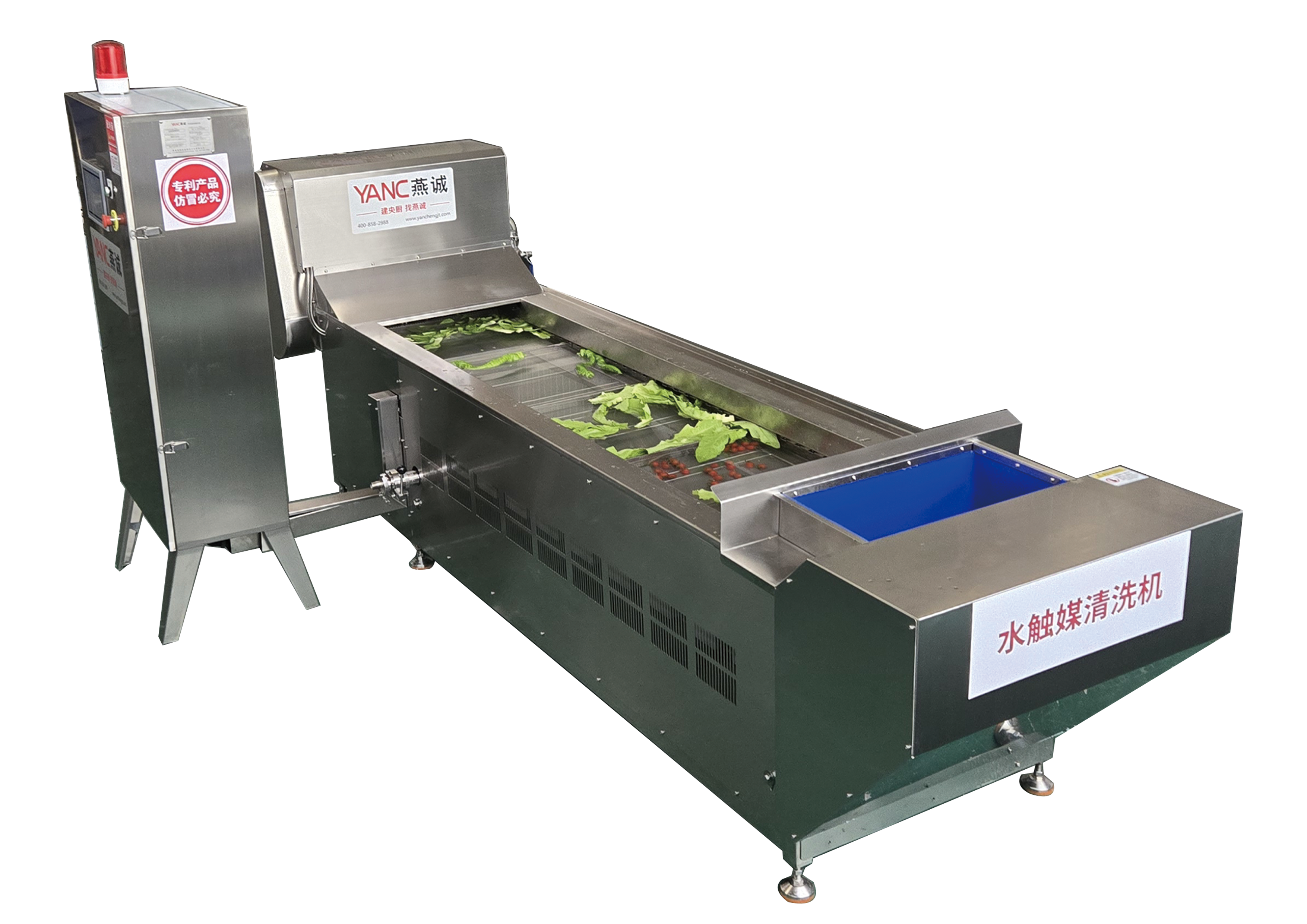

Water-Catalyst Food Cleaner_YC-V-STM3500

Rapidly eliminates bacteria, viruses, and harmful substances on fruits, vegetables, fresh meat, and kitchenware such as cutting boards. Efficiently degrades pesticides on the surface and inside of fruits and vegetables, as well as chemical residues in meat like hormones, clenbuterol, and antibiotics. Additionally, it preserves food freshness and restores the original taste and flavor without any additives.

- Overview

- Recommended Products

Product Description

Working Principle of the Water-Catalyst Washing Machine:

The water-catalyst washing machine operates based on water-catalyst food purification technology. It generates extremely high energy through the dissociation and reduction of water molecules. This energy is used to kill microorganisms and degrade chemical residues. The system effectively removes pesticide residues and disinfects by using tap water or mineral water as raw materials without any chemical additives. Through the dissociation and reduction of water molecules, highly reactive OH⁻ radicals are produced, which eliminate various pathogenic microorganisms (bacteria, viruses, etc.) and degrade toxic and harmful substances such as pesticides, hormones, antibiotics, and odor molecules.

After the purification process, the dissociated water molecules revert to water within 3 to 5 seconds. The entire process produces no toxic, harmful, or polluting substances. Additionally, precise time control ensures effective retention of nutritional components, making it completely safe for both humans and the environment.

Our company has independently developed the water-catalyst generating device, utilizing OH radical purification technology and physical degradation. This technology rapidly kills bacteria, viruses (with an inactivation rate of over 99.99%), and harmful substances on fruits, vegetables, fresh meat, kitchenware, and cutting boards. It efficiently degrades pesticides on fruit and vegetable surfaces and interiors (with a removal rate above 98%), and removes chemical residues such as hormones, clenbuterol (removal rate above 98%), and antibiotics in meat. Furthermore, it preserves food freshness (with a preservation rate up to 97%) and restores the original taste and flavor of the food.

This process requires no additives and poses no pollution or safety hazards to humans or the environment. It ensures the health and safety of various foods for consumers and represents the next generation of food purification technology.

Product Specification:

Item |

Parameter |

Dimensions |

3500 × 1400 × 1300 mm |

Power / Voltage |

8.2KW/380V(3-phase 4-wire system) |

Discharge Height |

680mm |

Outlet Diameter |

DN40 |

Inlet Diameter |

DN25 |

Productivity |

400-600kg/h |

Weight |

430kg |