From order placement to installation, from shipment to after-sales support, YANC delivers efficient and professional one-stop services to customers worldwide.

In today’s global business environment, product quality is essential, but smooth transaction processes and a robust service system are equally critical to long-term competitiveness.

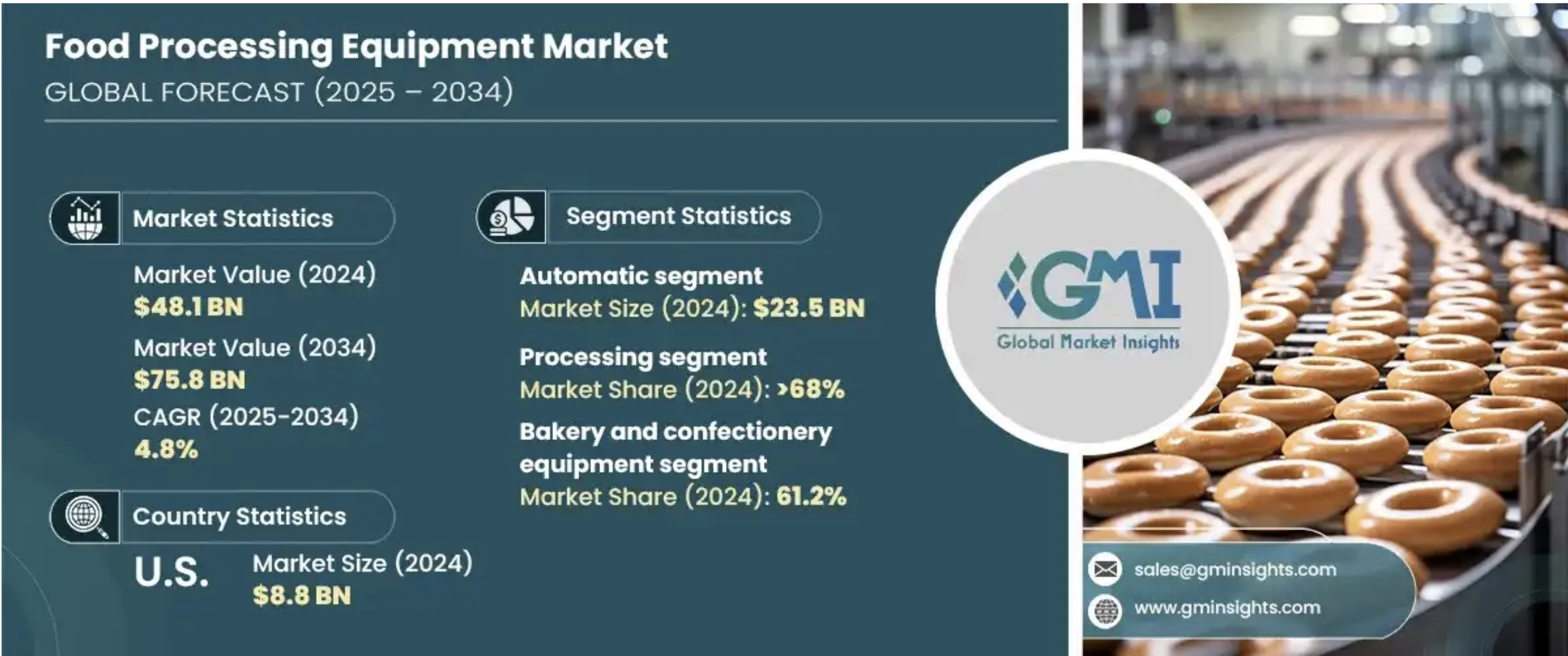

According to the 2024 Global Food Processing Equipment Market Report, the market value exceeded USD 48.1 billion and is expected to grow at a compound annual growth rate of more than 4.8% from 2025 to 2034, driven by rising demand for processed and packaged foods. Segments such as fresh-cut processing, central kitchen equipment, and washing-and-cutting solutions have shown particularly strong growth.

At the same time, overseas buyers increasingly prefer integrated “equipment + solution + installation + after-sales” procurement models, making End-to-End service a mainstream trend in global sourcing.

*Image source: Global Market Insights report

1) End-to-end professional consultation

Our sales team has extensive industry experience and provides timely, accurate responses to customer questions regarding specifications, performance, and compliance, offering practical and implementable solutions.

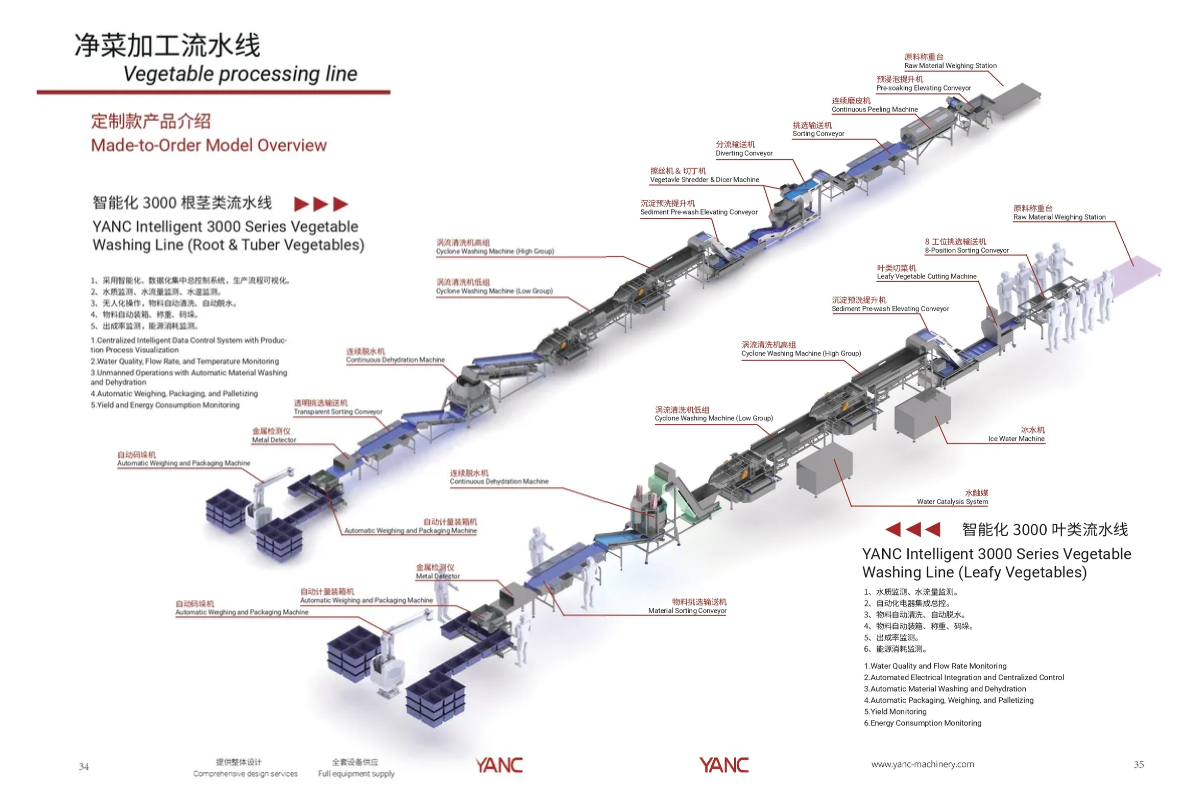

Based on customer requirements, market conditions, and application scenarios, we deliver tailored equipment configurations and technical support that maximize operational value.

[Example]

Small fresh-cut vegetable processing plants (Daily capacity: 1–5 tons/day)

Hourly capacity reference:

1 ton/day ≈ 125 kg/hour

5 tons/day ≈ 625 kg/hour (based on an 8-hour shift)

Recommended equipment configuration (compact and cost-efficient):

Selection rationale:

Compact layout, easy operation, minimal footprint, and fast commissioning—ideal for supplying local supermarkets and catering service providers. YANC can also provide layout drawings and localized installation guidance.

II. Export & Shipping: On-Time, Compliant, and Traceable

Global logistics network

Through cooperation with multiple international logistics providers, we offer a global and efficient transportation and customs clearance network that reduces delivery lead times.

Strict quality and packaging standards

Each machine undergoes multi-point inspection before shipment. Packaging is strengthened according to international transportation risk-control requirements, ensuring safe arrival at destination.

Real-time tracking and transparent information

Customers can check shipment details, logistics status, and estimated arrival times at any stage through our system, ensuring transparency and full visibility.

III. Installation & Commissioning: Professional, Standardized, Responsive

Professional installation team

YANC’s experienced engineers hold operation qualifications for multiple regions and ensure installations comply with process and safety standards.

On-site guidance and training

Upon completion of installation, we provide on-site operation demonstrations, manual walkthroughs, and necessary training to help customers achieve stable production quickly.

Efficient troubleshooting

YANC operates a 7x24 service hotline and remote diagnostic system. For urgent situations, our engineers provide real-time video support and step-by-step guidance to help customers restore equipment to stable operation as quickly as possible.

IV. After-Sales Service & Continuous Support: Care, Data-Driven Management, and Joint Growth

Warranty and maintenance programs

Standardized warranty, periodic maintenance, and upgrade services are provided based on product lines, helping customers reduce long-term operating costs.

Data-driven service management

Our customer management platform records equipment usage, maintenance logs, and upgrade requirements, turning insights into actionable improvement plans.

Customer success partnership

Regular follow-ups, satisfaction evaluations, and feedback collection help us build long-term partnerships and support customers in business growth and operational optimization.

V. Why YANC Is Trusted Worldwide

Seamless global-to-local service integration

Our cross-regional sales and service network ensures effective communication and timely support in each market.

One-stop solution provider

From early-stage consultation, design, and equipment selection to shipment and installation, we deliver an end-to-end service process that reduces coordination effort for customers.

Customer-centric continuous improvement

We leverage data-driven service optimization to refine procedures and standards, continually improving customer experience.

YANC remains committed to the service philosophy of professionalism, efficiency, and mutual success. Wherever you are, we will continue to support your food processing projects with strict quality control, strong execution, and comprehensive after-sales services.

We look forward to partnering with more global customers to advance the intelligent and international development of the food processing industry.

Hot News

Hot News