Vertical Rice Production Line_YC-SRCS300

The vertical rice steaming line is specially designed for central kitchen enterprises. It is a fully intelligent, fully automated specialized piece of equipment manufactured according to the requirements of central kitchens.

- Overview

- Recommended Products

Product Description

Rice, as one of the world’s most important staple foods, comes in a wide variety of types, such as Thai Jasmine rice, Japanese Koshihikari rice, China’s Wuchang rice, and Panjin rice. Different varieties of rice differ in taste, shape, and nutritional content, and thus require different processing methods. In response to this demand, our company has developed this vertical rice steaming line, which can accommodate the processing requirements of various rice types. It allows precise control of processing parameters to maximize the retention of nutrients and taste. Meanwhile, it adopts advanced automation technology to significantly improve productivity and reduce space, labor, and other costs.

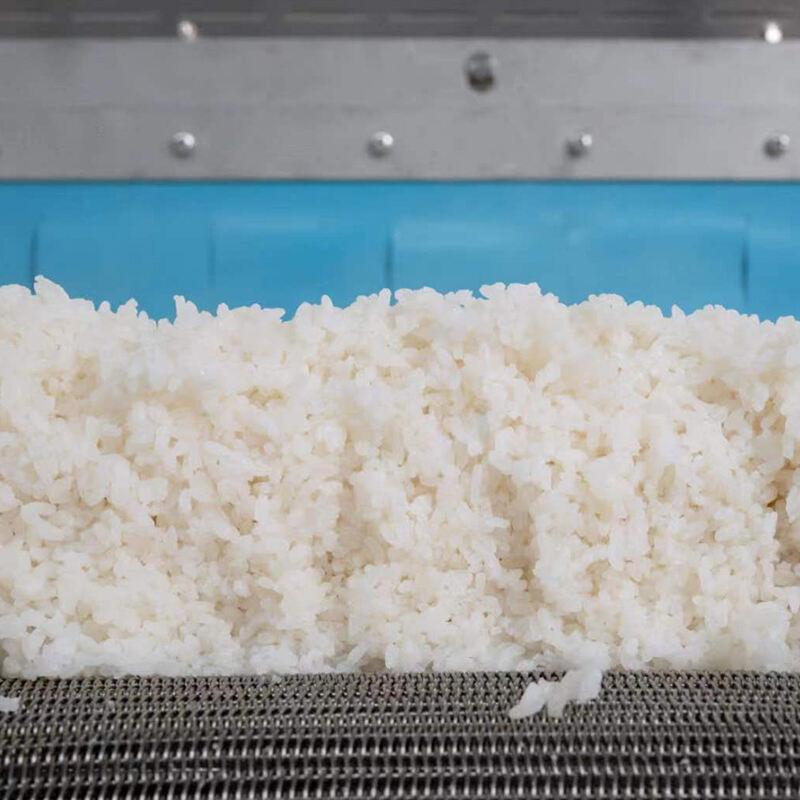

The rice is conveyed from the rice container to the soaking, measuring, and washing machine via an elevator bucket. After washing, the rice is soaked. Once the soaking is complete, the wet rice is transferred to the simmering machine via the wet rice conveyor. The soaked rice is first preheated, then simmered, and finally steamed. During the process, the soaking water is redistributed over the wet rice in subsequent stages, ensuring that the nutrients in the rice are retained to the greatest extent. As a result, the steamed rice becomes fuller, with a more intense and fragrant aroma.

Advantages:

1. The steam simmering and steaming machine allows independent control of preheating, soaking, and steaming times to meet various rice texture requirements. This equipment is widely used in central kitchens, rice deep-processing (such as fried rice), and the liquor industry.

2. Innovative three-layer stacked vertical structure greatly reduces floor space and improves space utilization. Visual touchscreen operation provides clear data and simple handling.

3. The machine features rice soup spraying, further enhancing rice quality.

4. Equipped with a rice loosening function, the rice automatically flips up and down during steaming, preventing obvious layering and ensuring consistent texture.

5. Rational spatial layout with fully openable side covers and multiple quick-release mechanisms make hygienic cleaning effortless.

6. Uses a cyclone drum washing method where rice and water spiral inside the drum. The rotation causes rice grains to rub against each other like hand washing, removing bran without damaging the grains. Under gravity, sand and stones settle at the bottom while rice flows with water into the measuring and filling machine, resulting in more effective cleaning.

7. The rice elevator adopts a dual-chain transmission structure, ensuring safety and hygiene.

8. The electrical control system includes voice prompts and a voice manual to better assist operators in understanding the machine’s operation.

9. Customers can opt for a networked service with data uploaded to a cloud server, enabling traceability, visualization, and remote control.

Product Specification:

Item |

Parameter |

|

Dimensions |

7200mm X 1920mm X 2970mm |

|

Power /Voltage |

Electrical connection |

6.27kW/380V (Three-phase Five-wire System) |

Inlet |

Size |

930*400*750mm |

|

Height |

750mm |

|

Size |

500mm |

|

Height |

445mm |

|

Steam consumption |

0.5 ton/h |

|

Diameter |

DN40 external thread |

|

Pressure |

Dynamic pressure 0.2 MPa, static pressure 0.5 MPa; equipped with steam pressure regulator |

Recommended boiler capacity |

≥0.5 ton/h |

|

Compressed Air |

Diameter: |

Φ10 |

Compressed Air Consumption |

0.7Mpa,360L/min, |

|

Water Inlet |

Diameter 1 |

DN25 |

|

Diameter 2 |

DN25 |

Water Consumption |

1.5–2 tons/hour |

|

Production Capacity |

300 kg of dry rice per hour |

|

Weight |

Approx. 2.9 tons (empty) |

|

Rice Yield Ratio |

2-2.4 |

|